Industrial Hose

Industrial hoses are flexible pipes used to transport fluids such as liquids, gases, and powders in various industries. Industrial hoses are designed for specific applications and are made from different materials depending on the type of fluid being transported and the environment.

Here are some details about industrial hoses:

- Material: Industrial hoses can be made from various materials, including rubber, PVC, silicone, Teflon, and metal. The material chosen depends on the fluid being transported, the temperature, pressure, and the environment.

- Type of fluid: Industrial hoses are designed for specific types of fluids, such as water, oil, chemicals, gases, steam, and food products. The type of fluid being transported determines the type of hose material and construction needed.

- Reinforcement: Industrial hoses can be reinforced with different materials such as synthetic fibers, wire, or metal to improve strength, durability, and resistance to pressure and temperature.

- Temperature and Pressure rating: Industrial hoses are rated for their maximum operating temperature and pressure. The rating determines the suitable environment and application for the hose.

- End fittings: Industrial hoses have end fittings that are attached to the hose to connect it to other components, such as pumps, valves, and tanks. End fittings can be made from various materials such as brass, stainless steel, or plastic.

- Bend radius: Industrial hoses have a minimum bend radius, which is the smallest radius that the hose can be bent without kinking or damaging the hose. The bend radius is determined by the hose material, diameter, and reinforcement.

- Standards and certifications: Industrial hoses may need to comply with specific industry standards and regulations, such as FDA (Food and Drug Administration) or UL (Underwriters Laboratories) standards.

Overall, choosing the right industrial hose for a specific application depends on the type of fluid being transported, the environment, the temperature, and the pressure. Selecting the appropriate hose material, construction, and end fittings can help to ensure reliable and safe transport of fluids in various industrial applications.

Contact With Us

chemicals Hose

Recommended For:

Conveying dilute chemicals e.g. Alums Liquor, Caustic Soda. Lime soltions, Dilute Hydrochloric Acid. Dilute Sulphuric acid

Tube:

Specially compounded EPDM, Black.

Reinforcement:

Single high tenacity synthetic yarn from 3/4" to 1 1/4" size & Double high tenacity synthetic yarn from 1 1/2" to 2" sizes.

Cover:

Specially compounded EPDM, Black.

Temp. Range:

-40°C to +100°C

Standard:

Exceeds IS: 7654

Chem Master XLPE Hose

Recommended For:

Tank truck, barge, ship, or storage tank transfer of a variety of chemical products. Chem MasterTM Plus XLPE contains a wire helix for full suction capability, as well as for routing through tight bends. Its Modified Cross-linked Polyethylene tube stock is 'best in class' and is designed for cleaning with 'open-end' 50 PSI steam or in a bath containing 10% (NaOH) @ +212 °F (+100°C). Cleaning in place (CIP) methods may be used.

Tube:

Type K (GatronTM Modified Cross-linked Polyethylene.) Tan. High chemical resistance.

Reinforcement:

Synthetic, high tensile textile cord with steel wire helix.

Cover:

Type P (EPDM). Black corrugated with orange stripe.

Temp. Range:

-40°C to +121°C (Normal Service)

Used For:

Transfer of >950 basic chemical products

Concrete Hose

Recommended For:

To handle the pumping of concrete with high head pressure from concrete boom truck and as a discharge hose on the delivery end of high pressure concrete pumps. Specially designed high abrasion resistant tube is most suited for handling wet concrete. Plaster or gout material.

Tube:

Specially compounded abrasion resistant & resilient natural rubber [Black].

Reinforcement:

Two layers of high tensile steel wire..

Cover:

Specially compounded abrasion resistant natural rubber [Black].

Temp. Range:

-40°C to +70°C

Standard:

Gates Proprietary Hose

Sand Blast Hose

Recommended For:

Highly abrasive material used in Sand Blasting applications including River Sand Garnets, Copper Slag, Coal Particles, Corundum, Cast Steel, Grit Glass etc. Specially designed for superior performance-longer life due to very low tube wear.

Tube:

Excellent abrasion resistant, Anti-static, Modified natural rubber [Black]

Reinforcement:

Single high-tenacity synthetic yarn for (3/4" & 1" sizes). Double yarn braid for 1-1/4" & 1-1/2" sizes.

Cover:

Specially compounded abrasion resistant & resilient natural rubber [Black].

Temp. Range:

-40°C to +75°C

Standard:

Meets IS: 5894

Air Water Hose

Recommended For:

All air and water applications requiring maximum flexibility in engineering Industry, workshop, shipyards, irrigation etc.

Tube:

Specially compounded Nitrile rubber, [Black]

Reinforcement:

Single braid of high tenacity synthetic yarn.

Cover:

Specially compounded high abrasion resistant Nitrile rubber for size from 1/2" to 3/4" sizes. Highly abrasion resistant modified natural rubber from 1" to 2" sizes.

Temp. Range:

-30°C to +82°C

Standard:

Exceeds IS: 446 Type 1, 444 Type 2

Pneumatic Hose

Recommended For:

All types of pneumatic tools in industries, compressed air applications and construction industry.

Tube:

Modified Nitrile Rubber, Black

Reinforcement:

Single braid of high tenacity synthetic yarn from sizes 1/4" mm to 1", single braid of high tensile brass coated Steel wire from sizes 1 1/4" mm to 2".

Cover:

Specially compounded high abrasion resistant nitrile rubber for sizes 1/4" to 3/4" [Black]. Highly abrasion resistant modified natural rubber for sizes 1" and above [Black].

Temp. Range:

-30°C to +82 °C

Standard:

Exceeds IS: 446 Type 2

Air Dril Hose

Recommended For:

Heavy duty, high pressure use on industrial construction and pneumatic mining applications, requiring an extra heavy duty hose with an oil resistant tube and abrasion resistant cover.

Tube:

Specially compounded Nitrile Rubber, Black

Reinforcement:

Single braid of high tensile steel wire.

Cover:

Option 1: Specially compounded highly abrasion resistant natural rubber, Black.

Option 2: Highly abrasion resistant modified Nitrile rubber, Yellow. in 1 1/2 size with perforated cover. Yellow cover meet MSHA flame.

Temp. Range:

-30°C to +82°C

Fuel Hose

Recommended For:

Dispensing all types of petrol and diesel fuels for service station pumps. A heavy duty hard wall hose which does not collapse in reel use or behind the nozzle in demanding service conditions.

Tube:

Specially compounded Nitrile rubber black, resistant to highly aromatic gasoline.

Reinforcement:

Single braided high tenacity steel wire.

Cover:

Modified Nitrile rubber. Available in Blue, Black, Green, Red and Yellow covers (smooth finish) as per below part nos.

Temp. Range:

-30°C to +49°C

Standard:

Meet and Exceed EN 1360: 2013 ATEX Approved

CNG Hose

Recommended For:

CNG applications for use in CNG kits in automobiles up to 2.1 Mpa - (Cars, LCV, HCV etc)

Tube:

Specially compounded oil resistant Nitrile Rubber, Black

Reinforcement:

Single high-tenacity synthetic yarn.

Cover:

Specially compounded oil abrasion resistant Nitrile rubber, Black

Temp. Range:

-40°C to +100°C

standard:

Meet SAE J30 R6 AIS 028, ARAI approved

Aircraft Fueling Hose

Recommended For:

All operations associated with ground fueling & de-fuelling of aircrafts. Suitable for applications with petroleum fuels having an aromatic hydrocarbon content not exceeding 30% by volume.

Tube:

Black, Resistant to aviation fuel, Nitrile Rubber

Reinforcement:

2 braid of High-tenacity synthetic yarn.

Cover:

Black, Anti-static, Non-flammable, Abrasion resistant, Blend of Synthetic Rubber

Temp. Range:

-40°C to -70°C

Standard:

Meets BS EN 1361:2004, El 1529:2014 Type C Grade 2, IS 5797:2016, Type C & Grade Q.

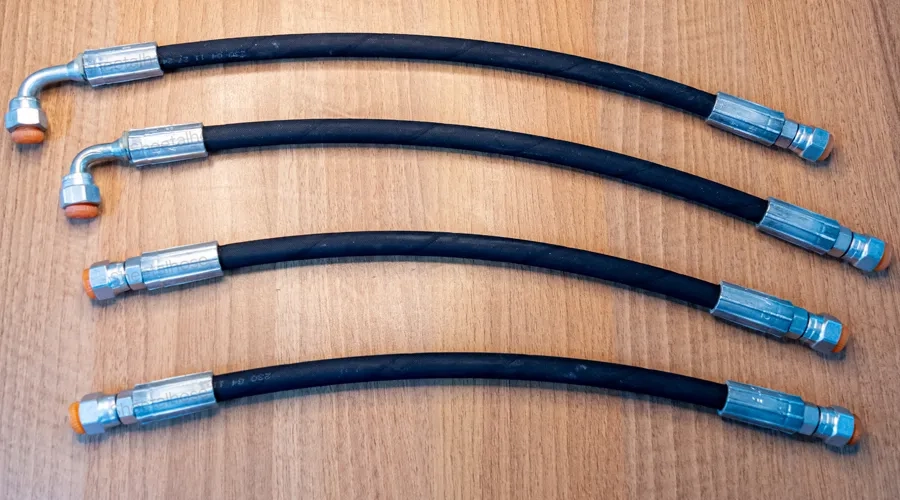

Features

Sheetal Hose Industries are the manufacturers and exporters of all type of Hydraulic Hose Pipe Fittings in Udaipur Rajasthan India.

- Single piece, Interlocking fitting design

- OEM focussed Production

- Hoses for every type of requirement

- Latest gen leak proof cold reshaping of tube with captive seal coupling, & rated upto 800 bar applications

- single piece, Un-jointed & Interlocking design

- Multiple coupling options

- Rust Prevention Coating & Packaging

- All fitting components are built to ISO 8435-1 / DIN 2353 specifications. (exceeds ISO 8434-1)